This problem can mimic what looks like warping, but rather than the part warping

off of the build plate, the individual layers seem to be warping upward, which I refer to as curling. You will see that the solutions to this problem are nearly the exact opposite of the ones given in the “Warping” page, since this curling issue doesn’t actually have anything to do with warping.

Turn on Active Cooling Fan

This problem of curling is most common when you print in PLA without an active

cooling fan, or with your active cooling fan not turn high enough. Whenever I

print in any PLA option, I will always have my active cooling fan turned on to 100% after the first layer is printed.

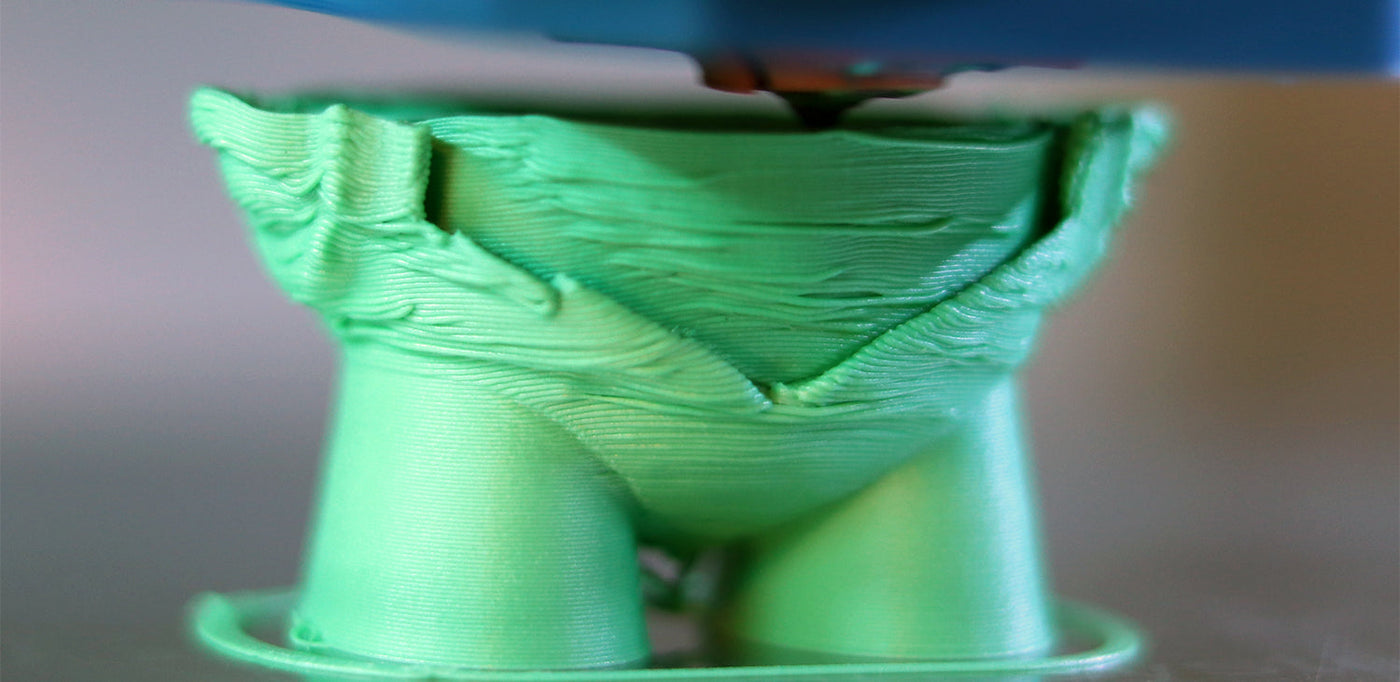

The photo below shows a PLA print with the same settings, but the one on the left

did not utilize an active cooling fan, and the one on the right did.

While you may hear me say in other places in this book that an active cooling fan

may reduce layer adhesion on some materials, this is not true for PLA. Printing

PLA without an active cooling fan will inevitably have an ugly look to it, and have

curling of top layers and angles.

This is also true for other particular materials, so you need to reference your manufacturer’s guide for whether an active cooling fan should be used or not for the filament you are using.

Too hot of an environment

This problem of curling could also arise if the actual environment is too hot for the

material you are using. You would not want to print PLA in an enclosed chamber,

since the ambient air will get too hot for the material to cool properly, even if you

have an active cooling fan on. PLA prefers to be printed in an open environment,

especially due to its low glass transition temperature.

The same is true for some other materials. In general, if the material you are printing does not have difficulty with warping, then you will not want to print it in an enclosed chamber. If your printer is enclosed, you will want to either remove the lid or leave the printer door open when printing in PLA.

Not enough time for layers to cool

If you are printing a small section on your print in which each layer prints on top

of each other in quick succession, then the previous layer may not have been given enough time to cool. This is why the “Minimum Layer Time” setting exists in Cura under the “Cooling” section.

In general, the majority of materials will be fine with a 3-5 second minimum layer

time. So if I were to set this to 3 seconds, and a layer completes in under 3 seconds, your printer will pause and wait before starting the next layer. If your layer were to complete in 1 second and then start the next layer without pausing, then the previous layer will still be hot and start to curl upward as the nozzle goes back over it.

It is advisable to also check the “Lift Head” box in Cura along with setting the “Minimum Layer Time”.

Too slow for layer height

If you are printing at a very slow speed, particularly for low layer heights, then it is possible your layers will start to curl upward. Lower layer heights have less rigidity than larger ones, meaning this problem can be more likely. A 0.3mm layer will be much more rigid than one that is 0.1mm, and be less likely to curl upward.

You can help mitigate this curling issue by either increasing your layer height or

increasing your printing speed.

Too hot of an extrusion temperature

You can also have curling of your layers if you set your printing temperature too

high. Make sure you are printing within the range of your particular material. This

is particularly true when printing with smaller nozzles and layer heights, since less volume of material is extruding per second when compared to larger nozzles and layer heights.

When printing with low layer heights on small nozzles, reduce your printing temperature to the lower range of the manufacturer’s suggestion if you are experiencing curling of layers.

Turn on support structures

This curling can happen on unsupported angles, especially on materials that cannot use an active cooling fan. When I print in ABS or ASA, I cannot use an active cooling fan as to reduce the risk of warping and delamination. This means that angles cannot be printed nearly as well as PLA with its use of an active cooling fan.

When printing in PLA, I generally have my support structures set to print at 55 degrees (with minor tweaks for different layer heights). When I print in ABS, I set my support structures to 45 degrees. This means ABS will require more support structures than PLA for particular angles. If I were to set my ABS prints to only require support structures at 55 degrees, than all angles between 45 and 55 will likely have curling.

Moisture in material

As with other problems that could arise, moisture in your material can also lead

to this problem of curling. If you have tried all of the previous solutions, and your

layers are still curling upward, then you will want to dry your spool.

Summary of Fixes and Precautions

• Make sure your active cooling fan is on if your material calls for it. 100% fan

speed is recommended after the first layer when printing in PLA.

• Make sure the ambient air is not approaching the glass transition temperature

of the material you are printing. PLA should not be printed in a fully enclosed machine.

• Have your minimum layer time set to at least 3 seconds in Cura so that each

layer has enough time to cool.

• Low layer heights have less rigidity, meaning increasing your layer height or

your print speed will help.

• Reduce your printing temperature, especially if printing at low layer heights on

small nozzle diameters.

• Turn on support structures and reduce the angle for when they are required,

particularly with materials that cannot use an active cooling fan.

• Remove moisture in your material if you tried all of the above methods.

United States

United States Global

Global