Ghosting in printing essentially refers to an “echo” where details in your print can be seen outside where they should be, which may also be called “ringing”.

The number one reason this occurs is having your acceleration and jerk settings too high. This is extremely common in 3D printing, especially since many printer manufacturers will auto set the default value for these numbers too high, since it will allow them to advertise faster printing times.

New printers that utilize "input shaper" or "vibration compensation" will calculate a way to compensate for these high vibrations, which is why they are able to print so fast without this ghosting effect.

A part with some minor ghosting is still entirely useable, so printer manufacturers may get away with calling something a successful print that we as makers would be upset with.

Keep in mind this issue should be reduced on a CoreXY or Delta machine, since the increased weight of moving the print bed on Cartesians will make this problem worse.

Reducing jerk and acceleration

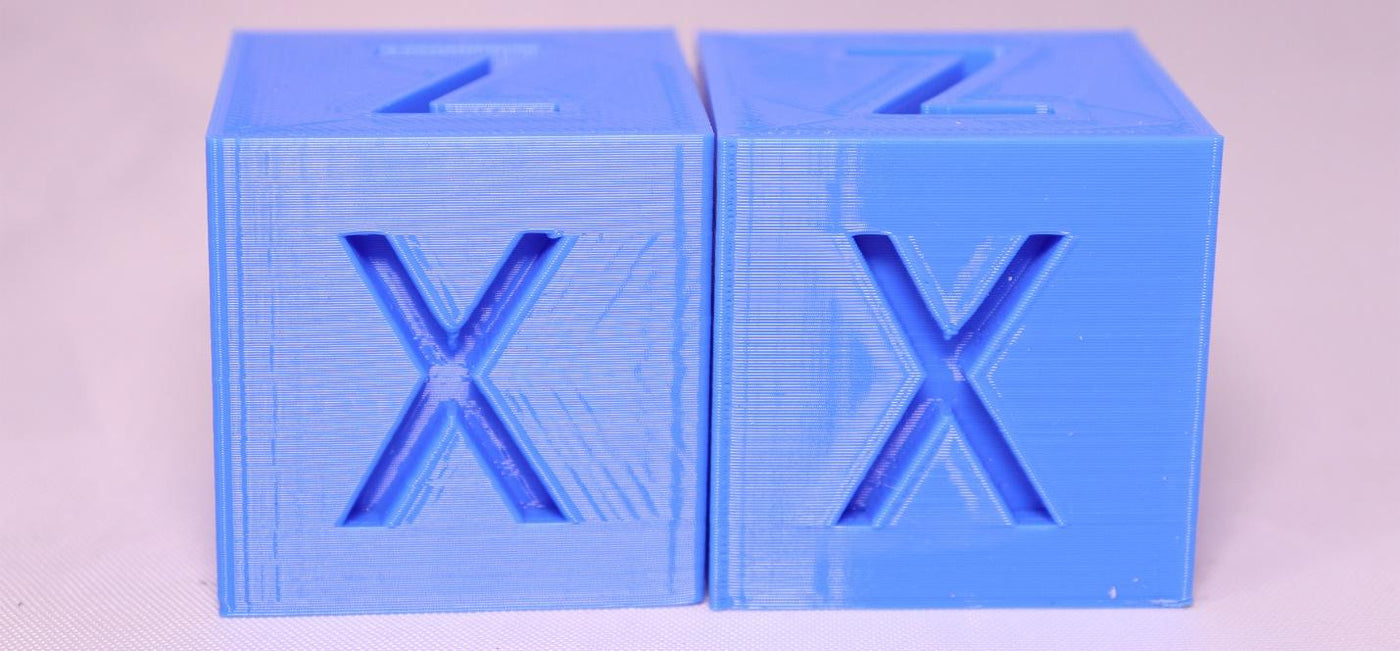

As you can tell from the photo above at the top of this page, there is a drastic difference in ghosting between the two examples. These parts were printed with every slicer setting being the same, except for Jerk and Acceleration.

Acceleration is pretty self-explanatory, but jerk refers to something you may not know unless you are involved in the 3D printing sphere. Jerk refers to the initial speed after a directional change. After stopping and starting again, your printer will start instantaneous at your jerk speed before then accelerating to your print speed.

The failed print on the left had accelerations of 3,000 m/s ² and a jerk of 30 mm/s while the print on the right had accelerations of 500 m/s² and a jerk of 12 mm/s – all other settings being the same. It has become clear to me that jerk and acceleration are the key factors when it comes to reducing ghosting.

The print on the left took 1 hour 36 minutes and the print on the right took 1 hour 50 minutes, so it is clear you will need to wait longer for your print to finish, but it is definitely worth it to have the quality you expect.

Again, new printers such as those made by Bambu are meant to calibrate for this increased accelerations and jerk as to not cause this ghosting effect.

Controlling jerk and acceleration right in Cura

This allows you to change these numbers without having flash your firmware. In Cura, this is located under the “Speed” section. If you prefer not to use Cura, then you will have to check within your slicer if this option is available. If it isn’t, you will have to manually change the Jerk and Acceleration within Marlin and reflash your firmware. These numbers are right within Configuration H:

You can also find out your current acceleration numbers by typing “M503” into Repetier Host or Octoprint, which will read out all of your current firmware settings. Almost all slicers now allow for acceleration and jerk controls, so this flashing of firmware shouldn’t really be needed anymore.

Some printers even have the ability to change your top accelerations and jerk settings on the LCD screen.

Add small cushions under printer feet

This is a very minor, but easy addition to your printer to help reduce ghosting. Part of the problem with ghosting is the rattling that occurs within the printer without anywhere to disperse it. If you have a very sturdy printer on a sturdy print area, most of the rattling ends up locating within the machine.

An easy fix is to grab some small foam cubes and place them under your printer feet. This will help to disperse vibrations through the machine into the pads, allowing you to print higher acceleration and jerk speeds with reduced ghosting.

Having a lighter carriage

The lighter the carriage, the less ghosting you will experience. This means ghosting will be more of an issue on a direct extruder than a Bowden, due to the increased weight of adding a stepper motor. We will still always prefer direct extruders to Bowden due to the extra amount of materials available to print, but one of the benefits to Bowden is the reduced weight.

You can also reduce the weight on your carriage via a smaller/lighter extruder stepper and/or carriage. The Hemera hotend/extruder is a great setup, but if you own one you will notice just how heavy it is. This weight might be too much for your printer, meaning you really need to reduce your acceleration and jerk to remove ghosting.

Belts too tight

Having belts too loose can cause Z-wobble (or even layer shifts), but going too tight can cause ghosting. There is no specific standard for how tight a belt should be, but I generally say they should be tight enough to have no droop and be springy to the touch. If they are so tight it is actually stretching out the belt, it can cause a reduction in dampening and add to your ghosting problems.

Having too tight of a frame

You almost always want to have a well-built, strong frame. Unfortunately, if you do not have any dampeners for your axis or vibration compensation/input shaper, this means that the vibrations from your machine won’t be as dispersed, resulting in increased ghosting.

Having this be too loose can result in Z-wobble. This means you are going to be trying to find the happy medium where you get no Z-wobble and no ghosting, something fairly hard to achieve (and a reason CoreXY is preferred over Cartesian).

You don’t want to go loosening screws on your machine in order to allow more dampening, which means it may be difficult to do much about this, other than adding cushions below the printer.

Summary of Fixes and Precautions

• Reduce your acceleration and jerk via Cura or your preferred slicing software.

• If not available in your slicing software or on your LCD screen, reduce via marlin and re-flash.

• Add small foam cushions below your printer feet to help disperse vibrations.

• Reduce weight on carriage if possible.

• Have dampening for your axis if possible.

• These problems are less of an issue on CoreXY and Delta machines

United States

United States Global

Global