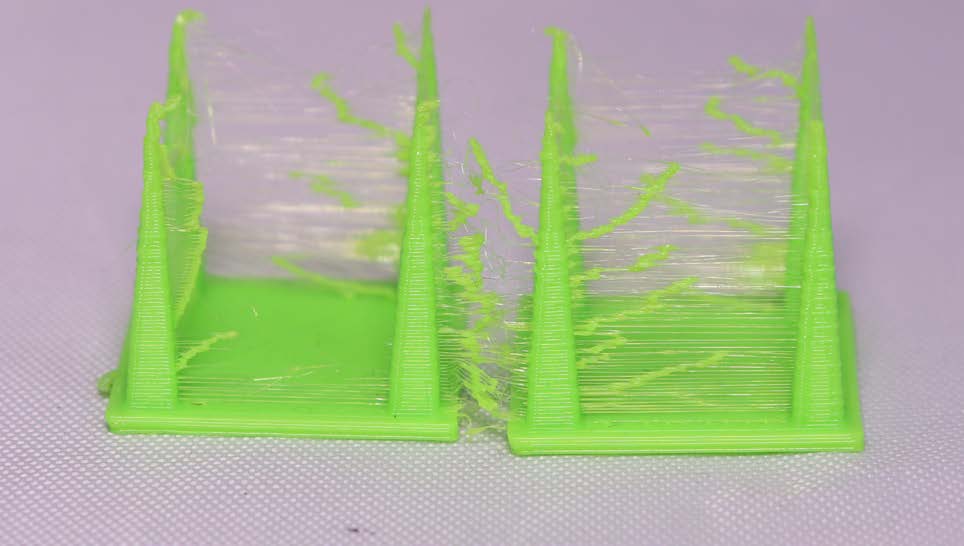

This article's failure is a result of excess material oozing out of your nozzle when

no material should be extruded.

Read the "Material Science" article

As with most problems we cover, if you learn the science behind polymers then it is likely you can figure out how to solve the issue. The specific issue of "Oozing" is directly covered in this article.

Increase retraction settings

Retraction occurs when your printer head is travelling as to reduce any excess material coming out of the nozzle. Essentially you will need higher retraction settings the further your extruder is from your hotend.

This means that when you use a Bowden setup you will need much higher retraction settings than when you use a direct extruder. You will also need higher retraction settings if there is a small gap between your direct extruder and hotend versus something like the Hemera, which has nearly eliminated that gap entirely. The smaller the gap between your extruder and hotend, the less retraction you will need, and the easier it will be to avoid blobs and strings on your print.

It is also very important to understand the material you are using. I can print something in PLA without any blobs or stringiness by just honing in my settings, but it is just about impossible to avoid some strings when printing in PETG. If you plan on printing in PETG, you will likely have to use a razor blade or a heat gun to remove the minor amount of stringing that will be inevitable.

Increase travel speeds

Since these blobs and strings will only occur when the hotend is not actively printing, you can help reduce the amount of time the nozzle is travelling by increasing the travel speeds. So long as your stepper motors and frame can handle the increased acceleration and speeds, you can bump your travel speed way up.

I currently have my travel speeds set to 200mm/s with my accelerations around 2,500mm/s/s on my CoreXY machines. You can try these numbers out on your machine, but if you experience a lot of machine rattling or hear any stepper motor skips, you will want to reduce these speeds. Many new printers such as those made by Bambu Lab will allow for even higher accelerations and travel speeds due to their vibration compensation.

The highest speeds you can go without experiencing issues will drastically help reduce these strings and blobs. Since you aren’t printing while the hotend is travelling, you should not experience any reduced quality in your prints with these high travel speeds.

Play around with Coasting

Coasting replaces the last part of an extrusion path with a travel path. Replacing

the last section of a print with a travel path will cause any oozed material to be used to print your part to reduce stringing. As you can see in our “Missing Layers and Holes in Prints” article, if you have coasting on when you do not have issues with stringing, it can result in holes on the side of your print.

That said, for the majority of inexpensive Bowden printers, you will likely see an

improvement in print quality when you utilize Coasting. This is particularly true

when printing in something like PETG which is more likely to cause stringing issues than PLA.

Dry or swap material

When a material has absorbed too much moisture, there are a myriad of printing issues that can occur, including a hairy or stringy print. If you ever hear a "popping" or "cracking" noise when you are extruding, then your filament has likely absorbed too much moisture.

Dry out the material or swap to a new spool.

Summary of Fixes and Precautions

- Read "Material Science" article

- Increase retraction settings

- Increase travel speeds

- Try coasting especially if you are using a Bowden style extruder

- Dry or swap material

United States

United States Global

Global