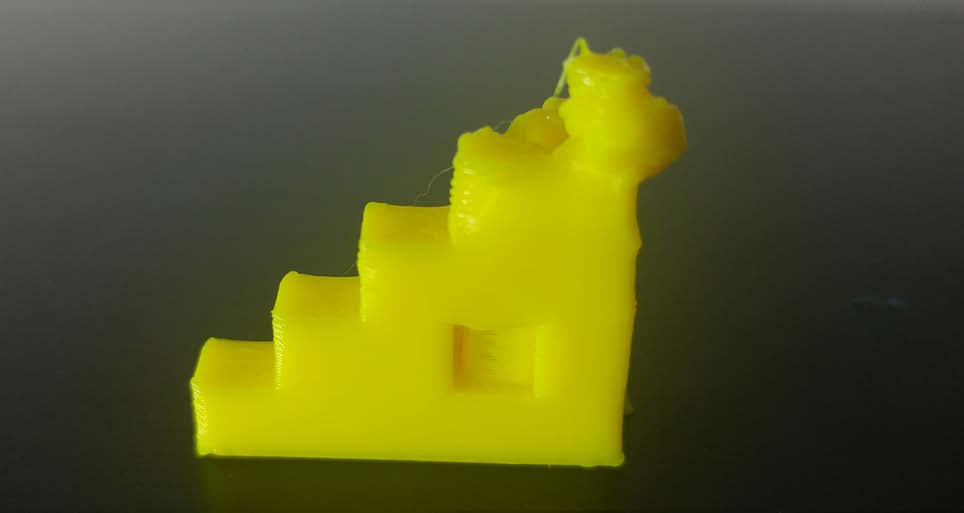

This issue will happen whenever you have a print with a very small surface area for any layer. This is most common when printing a part that comes to a point (think of a pyramid).

This occurs because there is not enough time for a layer to cool before the next hot layer is laid on top of it. This causes a print that comes to a point to get a melted, very ugly look to it.

There are a few very simple ways to solve this issue, but each comes with a bit of a drawback. Essentially we want to increase the time that the layer has to cool, or increase the rate at which the layer cools.

Print multiple objects instead of one

This obviously is not the best solution for every scenario since it will require you to print multiple of the same object, meaning you will waste material if you only have a need to print one.

That said - this is a preferred method if the model you are printing is quite small. This is because these thin areas will have time to cool as the print head moves to print the second object. This also means you won't have to worry about any oozing since the print head is not pausing allowing for oozing to occur.

Increase cooling fans

If you are printing with a material that allows for active cooling fans, then increasing the fan speeds will mean that each layer will cool faster.

This obviously has a drawback if using a material that cannot be rapidly cooled, such as Polycarbonate. But if you are printing in a material that allows for active cooling such as PLA, go ahead and crank up the fan speeds for when this thin part of the print is being printed.

Turn on/increase "Minimum Layer Time"

It will depend on what slicer you are using as to where you can find this and how the printer performs the operation, but you can always increase the minimum layer time:

In general, the majority of materials will be fine with a 3-5 second minimum layer

time. So if I were to set this to 3 seconds, and a layer completes in under 3 seconds, your printer will pause and wait before starting the next layer. If your layer were to complete in 1 second and then start the next layer without pausing, then the previous layer will still be hot and start to curl upward as the nozzle goes back over it.

This obviously has the drawback of increasing oozing since the nozzle will just be paused above the print, allowing for gravity and residual pressure to ooze out material.

Some slicers will just slow down your print speeds so that it takes the printer a minimum of 3 seconds in the above example to finish a layer. This also has the drawback that if you are printing a very small surface area layer, you can still get this ugly print since the hot nozzle is now moving very slowly over the same area.

Summary of Fixes and Precautions

- Print more than one object so that each layer has more time to cool

- Increase cooling fans so that the cooling rate is increased

- Increase the minimum layer time so that each layer has more time to cool

United States

United States Global

Global