Having strong layer adhesion is not only mandatory for watertight parts, but it is needed for clean, strong prints. If your individual layers do not stick together well, you are bound for a part that will break and peel apart.

Understand the material being used

Each material requires its own settings, including temperatures and speed. You need to make sure that you are using the proper settings for the type of material you are using, which are included on each of our product pages.

Refer also to the “Materials Science” page, before moving forward in trying to fix this problem.

Increase the extrusion temperature

One of the most common reasons poor layer adhesion occurs is because you are printing at too low of an extrusion temperature.

Following the manufacturer guidelines is normally a good way to prevent printing at too low of a temperature. This is particularly true with flexible filaments if you are printing them fast.

Try slightly increasing your extrusion temperature to see if it helps with this problem.

Print with a larger diameter nozzle

As covered in the “Material Science” page, you increase your layer adhesion by increasing the amount of entanglements between the layers. One way to increase this layer adhesion is to increase the surface area of your nozzle. Using larger diameter nozzles will help quite a lot with proper layer adhesion.

Slower print speeds

Similar to the explanation for using a larger diameter nozzle, you can also slow your print speeds down so that the nozzle is in contact with the layer below it for a longer period of time. With a larger nozzle and slower print speeds, the amount of entanglements between your layers will increase, meaning you will have stronger layer adhesion.

Whenever we are printing with something like ABS or ASA, we prefer a 0.6mm nozzle and we print very slow and very hot. We actually print ABS around 260°C and at around 35mm/s. But slow and hot will really help with making sure your parts have very strong layer adhesion.

Under Extrusion

Another reason for poor layer adhesion is under extrusion itself. If your extruder is depositing less filament than it thinks it is, you are bound to have weak layer adhesion.

Confirm you have the proper E-steps if you swapped extruders or have a DIY printer.

This could also be from temporary under extrusion, and we cover a lot of tips for that in the “Missing Layers and Holes in Prints” page. You will essentially want to make sure that your extruder gear is attached tightly to your stepper motor shaft and not have any free play, though you should read that page in full to get a detailed explanation.

Not Enough Torque

If your extruder motor skips, you will essentially be left with an under extruded or poor layer adhesion print. Please refer to the "Extruder Motor Skipping" page for more tips.

The best way to remedy this is to upgrade to a geared extruder, if you haven’t already.

Turn Off Active Cooling Fan

While having your active cooling fan turned on will benefit the majority of prints and materials with their surface quality, many filaments require you keep this active cooling fan off for proper strength and layer adhesion.

This not only helps to prevent warping, but will also help to achieve strong layer adhesion. Generally, the higher the heat capacity and density of the polymer, the more beneficial a cooling fan will be. For lower density polymers such as ABS, HIPS, etc. that are below 1.2g/cc, the fan is typically recommended to be turned off.

Make sure to check the manufacturers recommended settings for the particular material you are using, since many materials will benefit from increased layer adhesion when there is no active cooling fan.

Make sure material is stored properly

As with many other problems, make sure your material is stored properly. Old or wet filament can lead to issues that are very difficult to diagnose.

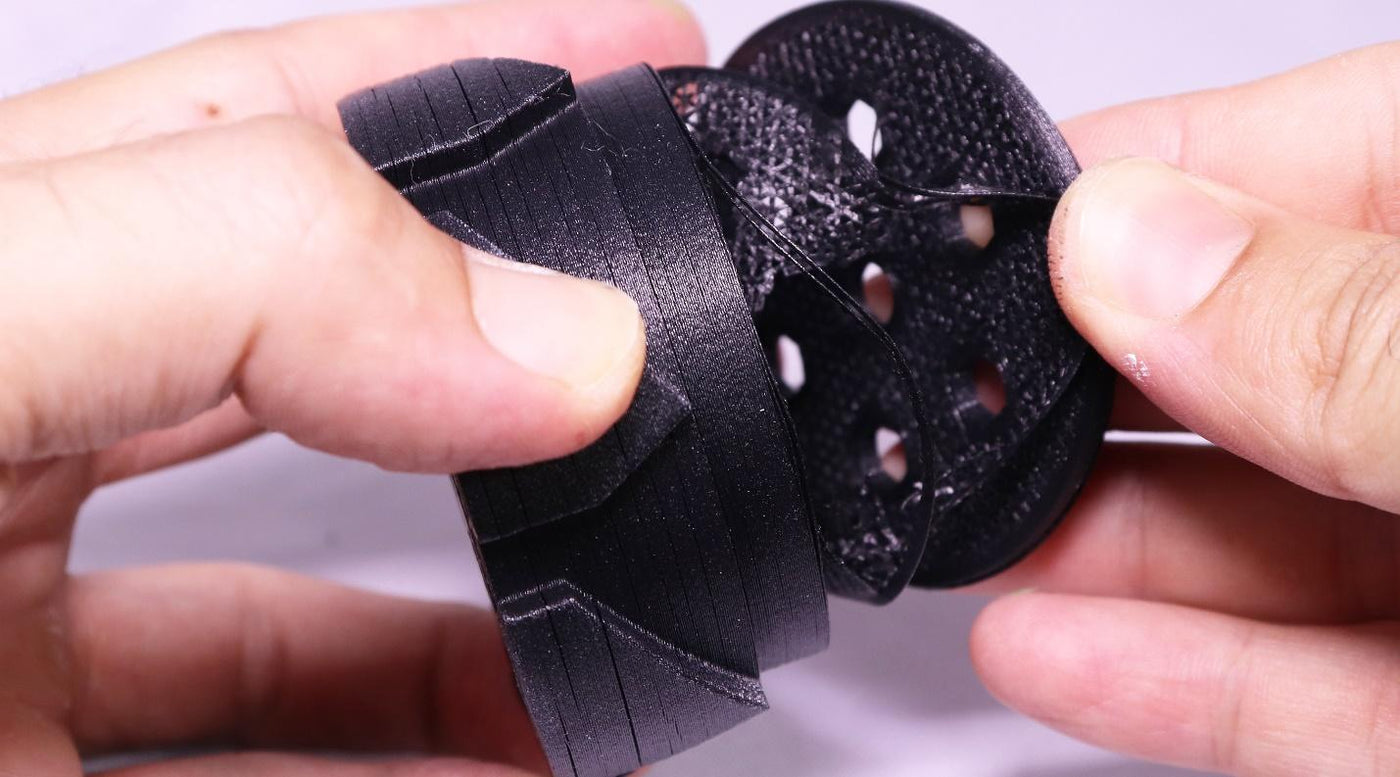

Delamination

We personally consider delamination a different problem than just poor layer adhesion. You can have extremely strong layer adhesion but still experience delamination when working with high warping parts.

Because of this – we cover this specific issue in the “Warping” page, since delamination is far more a symptom of high warping materials rather than just poor layer adhesion.

Summary of Fixes and Precautions

• Read the “Material Sciences” page.

• Check the manufacturer recommended print settings. Do not go faster or change the temperature outside their ranges to start your tests.

• Switch from using a carbon fiber reinforced material if continually experiencing issues, since carbon fiber reinforced materials are going to have more issues with layer adhesion than other types of filaments.

• If experiencing poor layer adhesion while staying within the recommended settings, try increasing the extrusion temperature slightly. I actually print ABS and ASA much hotter than most recommend.

• Use a larger diameter nozzle.

• Slow your print speeds down.

• Check E-steps and confirm you are not under extruding.

• Confirm you have enough torque and that your extruder motor is not skipping.

• Turn off active cooling fan if the particular material does not call for it.

• Make sure there is no issues with the material you are using.

• If experiencing delamination – check the “Warping” page.

United States

United States Global

Global